Adapt to the situation

The insurer's advice was the most obvious solution: a sprinkler system, but a sprinkler system needs a large amount of water. The location of the conveyor makes it difficult to supply the installation with the required amount of water, so this option was eliminated.

We first looked for a possible water supply. We found it in the generator building.

On the same floor as the bunker and the highest point of the conveyor belt are two 20,000 liter tanks. This is the water supply for the fire hose reels, it serves as cooling water and could also be used for this application.

Additionally, there was also space for the E-pump that is needed to increase the pressure.

With this information we came to a suitable solution: a low-pressure water mist installation. The VID FireKill low pressure water mist system consumes 60% less water compared to a sprinkler system, making it an appropriate solution due to this situation.

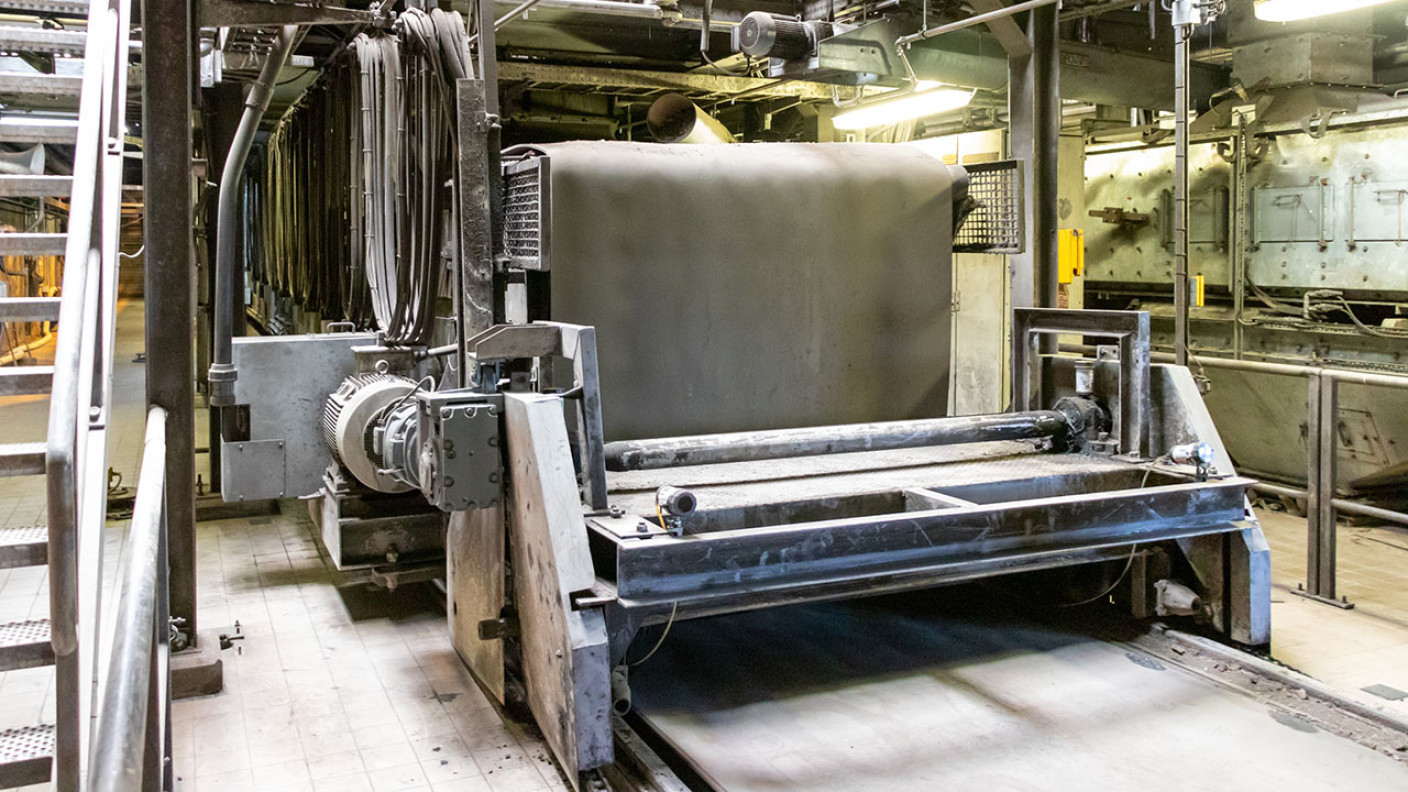

To be able to detect problems quickly, we use a linear temperature cable that runs along the bearings and motors. The installation is divided into nine sections that are controlled by the fire panel, which ensures the correct water mist section is activated when a fire is detected.